News

SFH Builds "Core" Competitiveness to Meet the Age of GB VI Emission Standard

2018-11-21

2018-11-21

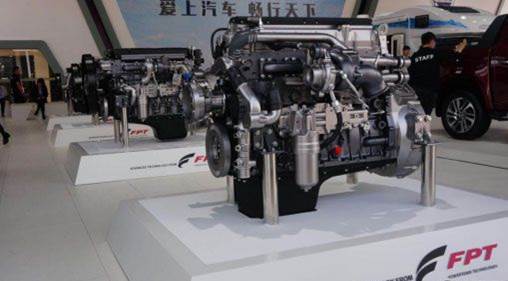

On April 27, the 2018 (15th) Beijing International Automotive Exhibition (Auto China 2018) with the theme of "Defining the New Life for Cars" is officially opened at the new and old China International Exhibition Centers in Beijing. As the "first" auto show after the CHINA VI Emission Standard for heavy-duty vehicles passes the review, the application and landing of the CHINA VI technologies also become the focus of attention at this auto show. Saic Fiat Powertrain Hongyan (hereinafter referred to as "SFH"), as one of China's leading diesel engine manufacturers, it participates with its GB VI product camp of mass-produced Cursor 13, Cursor 11, Cursor 9 and Cursor 9CNG, which is not only an abrupt rise based on its accumulated strength of CHINA VI technologies, but also shows the strategic layout for SFH to build the "core" competitiveness.

All roads lead to Rome---Hi-eSCR is probably the most suitable technology for GBVI

In last September,Limits and Measurement Methods for Emissions from Heavy-duty Diesel Vehicles (GBVI)(hereinafter referred to as "GBVI for Heavy-duty Vehicles") passed the technology review, which indicates that the relevant contents of the "GBVI" for heavy-duty vehicles have been basically settled. Compared withGBV, the carbon dioxide emission limitof GBVIis increased by 50%, the total hydrocarbon emission is decreased by 50%, the nitrogen hydride emission limit is increased by 42%, etc., and the actual road test and evaporative emission requirements are also added, which meansthat on January 1, 2020 and January 1, 2023,GBVI AandBemission regulations will be implementedseparately.

Compared withGBV, the carbon dioxide emission limit is increased by 50%, the total hydrocarbon emission is decreased by 50%, the nitrogen hydride emission limit is increased by 42%, etc., and the actual road test and evaporative emission requirements are also added.

From the international point of view, theemissionlimit of standardA of GBVI is slightly stricter thanEUROVI, while the limit of standardBis basically equivalent to the 2020 average vehicle limit specified in the America Tier3 emission standard. That is to say that standard of GBVI is equivalent to one of the most stringent emission standards in the world at present, and its complexity and difficulty are greater than that ofGBVI. However, both the EPA2010 Environmental Protection Standard (equivalent to EURO VI) and the EUROVI for EU countrieswhichimplemented in 2014 show the trend oftransferringfrom EGR to SCR in terms of international technology development.

EGR engine system adopts the principle of exhaust gas recirculation, so new combustion management system and exhaust gas post-treatment system need to be activated in order to further reduce NOx to meet the emission requirements, which means that SCR system needs to be added on the premise of using EGR+DPF, andHi-eSCR is more suitable to China marketfrom the perspective of cost performance

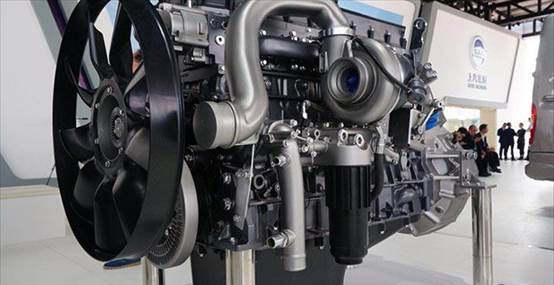

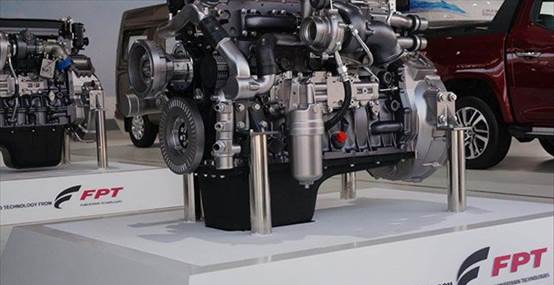

The

fourGBVI

engines exhibited by SFH are based on the highly efficient Hi-eSCR system developed

by FPTPowertrain Technologies. This emission post-treatment system is actually an

upgraded version of EUROV SCR and it abandons the exhaust gas recirculation

system and integrates DOC+DPF +SCR into a "small box" so as to

improve the combustion efficiency of the engine, in orderto

reduce PM generation. In addition, technologies such as high-pressure common

rail fuel injection and OBD remote control of the enginecouldreduce

NOx emissions by more than 95 % inSFH’sHI-eSCR system,

which can fully meet the upcomingGBVIstandard.

At the same time,sincethere is no EGR and DPF regeneration

treatment system, the whole-series of SFHenginescan

guarantee a lower temperature of the post-treatment system,which

could help toreduce

the maintenance interval and extra fuel consumption caused by DPF, and get the

maximum improvement in engine reliability, operation time and service life, increase

power by 5% while reducing fuel consumption by 10%, which is far better than

other products of the same class and become the best product with the best

economic benefits in the same class.

The

fourGBVI

engines exhibited by SFH are based on the highly efficient Hi-eSCR system developed

by FPTPowertrain Technologies. This emission post-treatment system is actually an

upgraded version of EUROV SCR and it abandons the exhaust gas recirculation

system and integrates DOC+DPF +SCR into a "small box" so as to

improve the combustion efficiency of the engine, in orderto

reduce PM generation. In addition, technologies such as high-pressure common

rail fuel injection and OBD remote control of the enginecouldreduce

NOx emissions by more than 95 % inSFH’sHI-eSCR system,

which can fully meet the upcomingGBVIstandard.

At the same time,sincethere is no EGR and DPF regeneration

treatment system, the whole-series of SFHenginescan

guarantee a lower temperature of the post-treatment system,which

could help toreduce

the maintenance interval and extra fuel consumption caused by DPF, and get the

maximum improvement in engine reliability, operation time and service life, increase

power by 5% while reducing fuel consumption by 10%, which is far better than

other products of the same class and become the best product with the best

economic benefits in the same class.

Abrupt risingbased on accumulated strength---SFHisin the leading position

GBIIIstartedin 2007,GBIVstartedin 2014,GBVstartedin 2017,GBVI-ais going to be implementedin 2020 andGBVI-bis going to be implementedin 2023,the time plateindicate that the upgrading of China vehicle emission standards has reached the stage of " an examination every three years". Chineseautomobile industry is striding into a new stage of high-quality development under the impetus of national policies, and the automobile industry is undergoing great changes from thinking concept to mode change. In the foreseeable future, China's automobile industry will struggle for research and development strength and technical reserves, while SFH will always be at the forefront ofcutting-edgeengine technology research and development.

SFH

was established in 2007 and went into operation in 2008. The 10 years of SFH’s

growing upis also the development history of China's motor vehicle emission regulations

and technology upgrading. Relying on the technology platform ofFPTTechnologies (hereinafter referred to as FPT), SFH realizes global technology

sharing and has been committed to developing efficient green power, from 3L,

9L, 13L to 11L, from traditional energy to new energy, fromGBIII toGBVI and

from SCR to the latest HI-eSCR post-treatment technology, so as to provide the

market withGBVI

products with leading technology and mature application. SFHhasnot only

become the

first enterprise to realize mass production of EUROVI

engines in China, but also achieved a significant increase insales

volume in 2017. Compared with 2016, the overall volumes doubled. With strong

technical reserves, SFH has accumulated its strength while facing the turning

point of switching emission standards.

SFH

was established in 2007 and went into operation in 2008. The 10 years of SFH’s

growing upis also the development history of China's motor vehicle emission regulations

and technology upgrading. Relying on the technology platform ofFPTTechnologies (hereinafter referred to as FPT), SFH realizes global technology

sharing and has been committed to developing efficient green power, from 3L,

9L, 13L to 11L, from traditional energy to new energy, fromGBIII toGBVI and

from SCR to the latest HI-eSCR post-treatment technology, so as to provide the

market withGBVI

products with leading technology and mature application. SFHhasnot only

become the

first enterprise to realize mass production of EUROVI

engines in China, but also achieved a significant increase insales

volume in 2017. Compared with 2016, the overall volumes doubled. With strong

technical reserves, SFH has accumulated its strength while facing the turning

point of switching emission standards.

At

the same time, with the development of the times, more and more users have

recognized the full life cycle cost. For any product, not only the initial

purchase cost but also the later use cost should be counted, which

including stable

and reliable quality and strong after-sales service will bring benefits to

ensure attendance.

At

the same time, with the development of the times, more and more users have

recognized the full life cycle cost. For any product, not only the initial

purchase cost but also the later use cost should be counted, which

including stable

and reliable quality and strong after-sales service will bring benefits to

ensure attendance.

In terms of quality system, SFH is also keeping pace with FPT. For example, sharing of the global purchasing chain makes the switching cost of spare parts lower when SFH developsnewproductstomeet emission standards. In addition, after 10 years of accumulation, thedomestic marketingshare of SFH engineshas increased a lot. The key parts suppliers are wholly owned or joint venturesofFPT global suppliers in China, which not only controls the cost but also ensures the quality of SFH engines in conformity with Europe products.

In addition tothe guaranteedquality, SFH has been committed to constructing the service system and continuously improving Its service capability.

The service network continues to expand.Meanwhile, in terms of after-sales support, SFH has also opened a24-hour after-sales service hotline and set up a unique "flight service" which enables users to get after-sales support more timely

and

efficiently.

TheGBVI

for heavy-duty vehiclesis both a challenge

and an opportunity for industrial development. TheGBVI power

will

become an important support foreachenterprise to enhance brand strength and seize the "core" competitiveness of the future

market in 2018.Speeding up iteration relying on technological progress and walking on the joint opening and innovation road

based on sharingofglobal resources,SFHis taking the lead in industry development with deep technical strength and laying a solid

product foundation for speeding up the implementation ofGBVI.